THE CO-OP COOKHOUSE SILO PROJECT WELL UNDER WAY

A preview of the 10,000 ton project at Cookhouse.

The fourth silo roof is being constructed with silo 1 and 2 up and silo 3 halfway.

SENMIN ELEVATORS BEING INSTALLED

ABC Hansen supplied the four +- 26 meter bucket elevators for the Senmin project for AECI in Sasolburg and is being installed in the …. Plant.

Stringent quality control all the way.

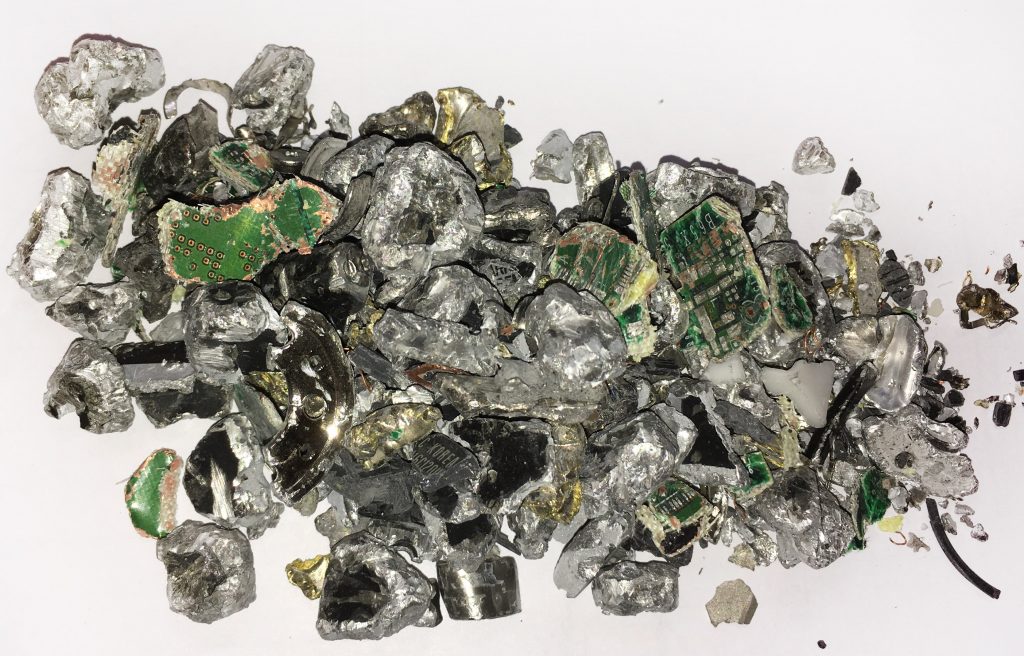

ABC HANSEN INSTALLS OWN SAND BLASTING PLANT:

Rather than sub-contracting sand blasting, ABC Hansen found it more efficient to sandblast its equipment prior to painting in-house.

A shipping container was lined and converted to allow for sandblasting. A sand recovery and sifting system ensures quality sand with the correct particle size is being used.

HIPPO MILLS CROWNS A WINNER

90 years after Arthur Collins showed his first Hippo Mill at the Royal Show at Pietermartizburg, Hippo Mills, keeping up the tradition as an annual exhibitor at the show, highlighted the humble origins of Hippo Mills during a dinner where the grand- and great-great grandchildren of Arthur remembered their far-sighted grandfather.

In 1892 Arthur Collins, a young English inventor-engineer set foot in South Africa and after having developed many products still in use in the mining industry, and with the later the collaboration of his son Frank, in 1928 exhibited the first South African made hammer mill at the Royal Show in Pietermartizburg.

Needing a brand, the inventors turned to the news story of the year, being the travels of Hubert (later established to have been Huberta) the hippo along the east African coast from St Lucia in Zululand to deep into the Eastern Cape. Her death at the hands of farmers had the country in mourning. So the mill was called Hippo in commemoration of this spirited animal.

Today ABC Hansen is still manufacturing Hippo hammer mills, as well as a range of other agricultural equipment, along the same technology this gifted engineer envisaged. Cast iron, bolt together construction allowing any part to be replaced when worn and allowing movement between parts to avoid stress cracking in the structure due to vibration.

Moving with new market demands, today’s Hippo mill has overcome the dust problems inherent with hammer mills, a mechanical in-feed mechanism allowing for optimal performance, more efficient cyclones, easy dismountable delivery tubes, enhanced fan performance etc. However in essence, a Hippo mill remains a Hippo mill and is still considered a mill for a lifetime.

Today the range of mills from 4kW to 90kW has not only traditional farm & village applications but industrial applications for large industry and feed mills are more prevalent than ever. And Hippo mills are not only sold throughout Africa but also the USA, Germany, Denmark, Australia, Nieu Zeeland, Papua New Guinee, the Carribbean Islands and many other destinations.

At a function at the Royal Show on May 26 – 90 years after its first appearance there – the 3 granddaughters, one great and another great-great granddaughter of Arthur Collins presented on behalf of ABC Hansen, a free Hippo mill to Mr. Christopher Chilenje of Malawi – a Hippo owner donating this mill to a community near Mzimba some 400km north of the capital Lilongwe, who showed greatest need of a village mill from all the contestants who entered into the Hippo competition. ABC Hansen shall be there when this mill is presented to the community, allowing processing of more than 200kg per hour of maize meal.

Hippo Mills will be there to present this award to the community and will keep you posted here about this event.

NAMPO SHOW

The biggest agricultural exhibition in Africa and beyond was another great event for ABC Hansen.

A total of more than 1,500 persons visited the ABC Hansen Grain, Scanwood and My Silo stands over the 4 days of the show, with over 400 official enquiries taken.

HUBERTA THE WANDERING HIPPO SURE GETS AROUND…

Huberta the wandering Hippo has been at it again. This year only she visited the USA, Germany, Holland, Australia, Nieu Zeeland, Papua New Guinee and the Carribbean apart from local African travels to destinations such as beautiful Kenya, the Pearl of Africa – Uganda, the Warm Heart of Africa – Malawi, the giant of Africa – DRC, mineral rich Angola, the green island of Mauritius and the eighth continent – Madagscar, apart from our Southern African countries.

Hippo and Universal mill exports to Pleasant Hills Grain of Nebraska is picking up speed with another container of 28 Hippo Baby as well as Hippo 47’s, 57’s and 69’s on its way.

Go to the ABC Hansen shop and get your discounted copy of “Huberta’s Journey” – a wonderful book for old and young, showing the joyful and finally disastrous interaction between humans and our wild animal brethren.